0

Your cart is empty

T/T: A telegraphic transfer (T/T) is an electronic method of transferring funds utilized primarily for overseas wire transactions. Telegraphic transfers are also known as telex transfers, abbreviated T/T; T/Ts can also refer to other types of transfers.

L/C: An L/C at sight is a letter of credit (L/C) that is payable immediately – within five to ten days – after the seller meets the requirements of the letter of credit.

Melt Flow Index (190°C/2.16 kg): 0.7 to 1.2 g/10

Moisture Absorption (23°C, 50%Rh): min 0.01 - 0.03 %

Ash Content: ≤ 1%

Form: 3 mm granules

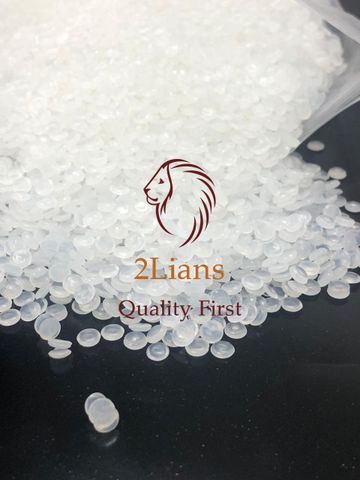

LDPE Repro pellets - Clear pellets

Polyethylene (PE plastic) is durable, and has low stiffness, but has high toughness and impact resistance as well as low friction.

Low-density polyethylene (LDPE) is a plastic material suitable for the molding processes for thermoplastic mold processing and good mold making capabilities.

Application: Its main uses are in packaging (plastic bags, plastic films, seismic screens, plastic bottles, etc.)

LDPE is widely used to produce different types of containers, wash bottles, tubes, LDPE plastic bags, and various laboratory equipment. Its most common use is in making plastic bags.

Low density polyethylene (LDPE) is a thermoplastic made from ethylene monomer. This is the first polyethylene layer of Imperial Chemical Industries (ICI) manufactured in 1933 using a high-pressure process through a free polymerization. Its production uses the same method today of LDPE Repro pellets - Clear pellets

LDPE Repro pellets - Clear pellets

LDPE scrap is determined by a density range of 0.910-0.940 g / cm3. It does not react at room temperature, except for strong oxidizing agents, and some solvents cause swelling. It can withstand continuous 80 ° C and 95 ° C temperatures for a short time. Made of translucent or opaque variants, it's quite flexible and tough.

LDPE has more branches (about 2% of carbon atoms) than HDPE plastic, so its intermolecular forces (bipolar-bipolar attraction) are weak, its tension is lower, and Its resistance is higher. In addition, because its molecules are not tightly packed and less crystalline due to lateral branches, its density is lower.

Chemical resistance

- LDPE has excellent durability (no attack / no reaction) with dilute acids and concentrates, alcohols, bases and esters.

- Good resistance (slight attack / very low chemical reaction) to aldehydes, ketones and vegetable oils.

- Drought tolerance (significant reaction / chemical reaction, suitable only for short-term use) for fatty and aromatic hydrocarbons, mineral oils, and oxidants. Poor resistance and not recommended for use with halogenated hydrocarbons.

See more ldpe film scrap